Updated with latest GHS labeling requirements for 2021!

Understanding GHS labeling requirements is essential when creating custom labels for potentially hazardous products. Although GHS has now been implemented or partially implemented in approximately 67 countries, it’s easy to overlook evolving standards when designing your labels.

In this guide, you’ll learn about GHS components, classification categories, required label elements, and global updates like GHS Revision 8. We’ll also address container types, small container labeling practices, and how to stay compliant with both GHS and the OSHA HazCom Standard.

Not so long ago, working with hazardous chemicals was especially dangerous because, often times, employees didn’t know exactly what they were dealing with. For example, the container may have come from a company in another country.

Even if they did label it, the message may have provided little in the way of helpful information. Workers would have to use their best judgment when transporting, storing, or extracting the chemical.

Then, in 1992, the United Nations decided to come up with a solution to this persistent problem. The result was GHS.

The GHS was developed by the United Nations to create a single, coherent international framework for classifying chemical hazards and communicating safety information.

The three key components of GHS are:

Since its introduction, GHS has evolved through eight major revisions. The U.S. adopted its own aligned version in 2012 via the OSHA HazCom update. The aim is uniform communication that reduces confusion, accidents, and compliance delays.

GHS stands for Globally Harmonized System of Classification and Labeling of Chemicals. It is an internationally-recognized standard for labeling containers that hold hazardous materials. Currently, more than 65 nations have adopted some version of these standards. Although the original framework was published in 1992, the process of countries actually applying the standards has proven to be a long one.

GHS implementation varies by region:

These examples show how GHS is globally embraced, albeit with jurisdiction-specific variations.

It’s important to point out that the GHS is only a collection of guidelines and not legal obligations. Each country is free to apply them as they see fit.

That said, the GHS provides participating countries with a framework for creating a compliant hazard communication system. The main goal is to make it easy for workers to immediately understand what kind of chemical is in a container and what the risks are for handling it. This system covers:

Before implementing the GHS, standards for labeling chemicals were different all over the world. If company A in Canada received a shipment of chemicals from company B in Germany, the different label types could make it confusing to figure out what exactly is in a container.

Unfortunately, any amount of confusion when moving or otherwise handling dangerous chemicals can result in major problems, including death. Keep in mind, too, that some companies do nothing but transport and handle these types of chemicals, so a consistent method for quickly labeling and identifying them is important.

Furthermore, shipments would often get stalled at different borders because one country’s laws about certain chemicals and to transport them would differ from another’s.

In short, the GHS ensures that a chemical originating from the U.S. is labeled the same way it would in China. While various countries may still have differing laws about different chemicals, these labels streamline the process of assessing their associated risks.

For manufacturers, the GHS also reduces redundant labeling systems and improves supply chain communication. Distributors benefit from consistent international classification, and workers gain clearer warnings and emergency instructions – critical in preventing exposure incidents and reducing response times.

Another component of the GHS is the Safety Data Sheet (SDS). These sheets provide important information about chemical hazards through 16 different sections, including:

The main purpose of an SDS is to give workers instructions for dealing with potential worst-case scenarios like direct exposure to the chemical or a major accident.

Each section in a GHS-compliant SDS contributes to hazard communication. For instance:

Understanding each section helps employees and emergency responders act swiftly and correctly in the event of chemical exposure or accidents.

In the United States, OSHA utilized GHS resources to create a comprehensive update to the prior protocol, the Hazard Communication Standard. This was done in 2012 after decades of work was undertaken to revise “HazCom.” This process is a good example of how a country could work within the GHS framework to create laws that fit their unique needs best.

This new standard is generally referred to as “HazCom 2012.” One of the biggest changes was an emphasis on ensuring employees who work with or near hazardous chemicals understand the risks involved. For companies operating in regulated sectors, understanding regulations for clinical trial labeling is equally critical to avoid violations.

Dr. David Michaels, the director of OSHA, confirmed as much during the speech he gave to introduce the Hazard Communication Standard (HCS). He mentioned that the first version that past in 1992 gave workers the right to know about these chemicals, but that this new version would ensure they also understood what these chemicals were capable of and what to do in case of an accident.

Nonetheless, it took four more years for the OSHA Hazard Communication Standard to become aligned with GHS standards and enforced as law. This timeline is understandable, though, seeing as how the changes OSHA made affected 43 million employees across 5 million different workplaces.

The biggest changes to the old procedures centered on:

The related dates of compliance were spread out across four deadlines:

Therefore, at this time, every company that labels containers storing chemicals must follow HazCom 2012’s rules. While GHS standards are only a guideline, HazCom 2012 is a legal mandate.

Impact Summary: HazCom 2012 impacted over 43 million U.S. workers. It aligned U.S. regulations with GHS and mandated uniform chemical labeling practices, strengthening worker comprehension of hazardous substances.

As we touched on earlier, the GHS isn’t international law. The hope is that all members of the UN will eventually adopt these guidelines in their entirety, but countries are free to pick and choose which recommendations they wish to apply as law.

While global guidelines aim for harmony, each nation tailors it’s container labeling to fit operational constraints, so it's essential to verify regional compliance rules.

A GHS classification is used by manufacturers to communicate the main risks involved with a specific chemical. Some examples of these classifications would include:

This information is provided where the GHS hazard statements go, which we’ll cover in more detail in the following section.

The letter-number combination that precedes the GHS hazard classification is only for reference. There are 80, so these “H codes” make it easier to find the appropriate label. The European Union has another 26.

However, it’s the actual statement that must appear on the label in order for it to comply with the GHS framework.

In total, there are 29 GHS classification categories for unique hazards. These are broken down into three main categories:

The GHS provides objective standards for classifying each of these categories.

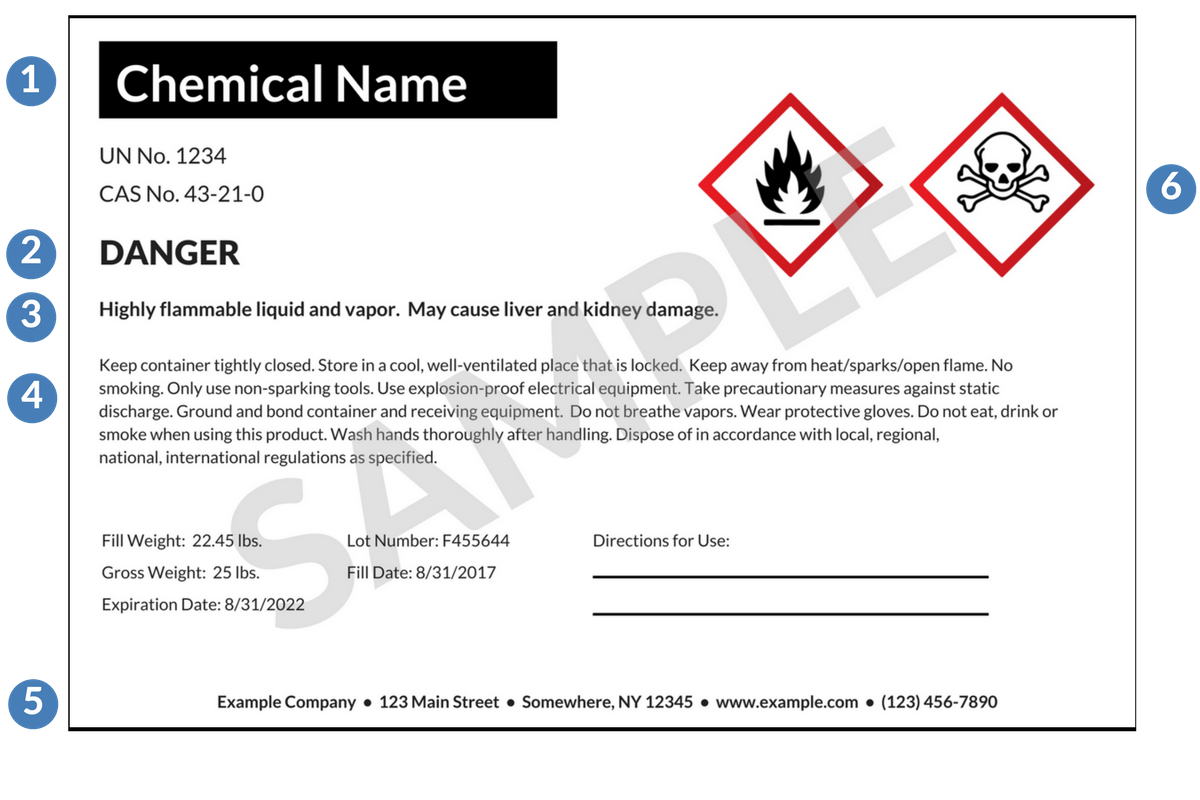

All hazardous chemical labels must be made with six different indicators. These GHS label requirements are meant to succinctly communicate key information about what is inside.

However, the GHS takes into consideration that, sometimes, it’s not possible to keep workers safe with only these six label requirements, which is why it also allows for supplemental information.

This requirement identifies the actual hazardous chemical inside the container. It is up to the responsible party to decide how they will do this. Common methods include:

However, the same identifier must be used on the GHS label and the accompanying SDS under section 1.

GGHS signal words clarifies the relative level of danger a hazardous chemical represents. There are only two GHS signal words, though:

The former is used for lesser hazards while the latter is for labeling those with greater degrees of severity.

GHS label requirements also specify that only one of these words can be used. Therefore, even if a chemical has two hazards associated with it – one requiring “Warning” and one requiring “Danger” – both GHS signal words will not appear on the label, only “Danger” as it is the more severe of the two.

GHS hazard statements explain the nature of the chemical’s hazard. All GHS hazard statements that apply to a certain chemical must appear on its label. Unlike GHS signal words, there is no hierarchy wherein one statement would be sufficient to cover lesser hazards.

That said, to save space, these statements can be combined on GHS labels, so long as they still communicate the vital information.

Each hazard category has its own hazard statements, which supports the kind of consistency the GHS was created to provide in the first place. Again, though, some leeway is approved in order to improve readability and reduce redundancies when using GHS hazard statements.

The point of these descriptions is to quickly alert workers to the kinds of precautions they should take to minimize the chances of exposure, improper storage, or incorrect handling of the hazardous chemical.

There are four precautionary statements that can be used on GHS labels:

A forward slash (/) is used whenever a classifier wants to shorten statements, as in the case of lists. For example, the precautionary statement “Do not breathe fumes/sprays/mist” would mean, “Do not breathe fumes, sprays, or mist.”

Usually, different precautionary statements are to be read as independent of one another. However, the OSHA Hazard Communication Standard does allow for some flexibility. If necessary for the sake of readability and clear communication, statements can be combined or unnecessary ones left out.

This is a fairly straightforward GHS label requirement. The party responsible for the container and its contents – whether that be the manufacturer, distributor, importer, etc. – must include their contact information on the label.

These GHS symbols are used to quickly let workers know about the chemical inside, even if they’re not close enough to read the other information provided. The standard for these GHS symbols is to have a red square set on a point against a white background with a black symbol inside. The symbol must be big enough that it can be easily recognized by a worker.

Red squares set on a point that don’t contain images are not GHS symbols and these types of pictograms are prohibited from a container’s label.

Label consistency is guided in part by International Graphic Measures, which aid in standardizing visual hazard communication across borders. The GHS symbols used by OSHA are used all over the world. Although nine are internationally recognized, though, OSHA only enforces the use of eight of them:

If a laIf a label producer feels as though there is other information that workers should know about when handling, transporting, or storing a chemical, the GHS framework provides room to supply it.

One common example may be an additional hazard that isn’t covered by the nine GHS symbols we just covered. Another is information about the kinds of protective gear workers should wear when handling the container. Other examples would include:

There is no specific format label makers must follow in order to comply, though. The only rule is that the supplemental information cannot detract from or contradict the required information GHS labels must include.

There are two types of containers GHS labels may appear on: primary and secondary. The rules for labeling these different types are slightly different.

Primary chemical containers include:

These are the types of containers that are used to transport chemicals from the manufacturers. They should include all the relevant GHS requirements we covered above.

Labels provided by suppliers should never be removed, modified, or defaced. If one of these labels needs to be replaced, the new one must contain the same exact information.

These containers tend to be much smaller than primary ones. Common examples include:

They usually contain chemicals that have been transferred from their primary container. Labels for these containers must still follow the applicable GHS framework, except when the following applies:

Companies are also given a lot of flexibility for how they wish to label secondary containers. They can strictly follow the GHS framework, adopt rules used by the supplier, or come up with some version of their own.

GHS applies to many container formats:

Label material must be durable and legible under transport and storage conditions – especially when using methods like shrink sleeve labeling.

In the United States, there are no specific requirements for labeling small containers. The only instruction is that labels must be prominently displayed and legible. Unfortunately, this can provide quite the challenge for companies dealing with small bottles and vials.

Unlike in the European Union, there are no exceptions for these tiny containers. OSHA demands that labels on every container include its contents’:

Fortunately, there are guidelines that accommodate the demands of smaller containers. The following options can be used to ensure that the required information accompanies containers that aren’t big enough to have traditional labels attached:

The primary container must also mention that further information is provided on its packaging’s label.

Of course, there could be still be situations where containers are too small for even this much information, but OSHA has provided further instructions for those.

Common Challenges:

Solutions:

ThThe packages used to transport these small containers must feature labels with the following information:

The complete label on the outside of any package a small container is kept in must always be maintained.

Seeing as how GHS requirements are just guidelines, other countries have also interpreted them to accommodate companies that use small containers. Here are specifics for 11 other countries, including the EU:

Understanding GHS labeling requirements is critical when creating custom labels for potentially hazardous products. Although GHS has now been implemented or partially implemented in approximately 67 countries, it can be easy to overlook these standards when designing your labels -- particularly if you aren't staying up-to-date on new developments. Let's take a closer look at some new information about GHS labeling requirements you'll want to keep in mind for your product labeling.

Back in 2018, the Occupational Safety and Health Administration (OSHA) announced that the agency had plans to update the existing U.S. Hazard Communication Standard. Established in 2012, the standard has been ripe for an update since 2014. However, OSHA has pushed back the deadline on several occasions. At one point, it looked like the HazCom Standard would receive an update by the end of 2019. But when that date came and went with no updates released, OSHA announced that several important steps of the process still remained and that the HazCom Standard would not be updated before 2021.

That means that the current HazCom Standard is aligned with the third version of GHS, despite the fact that GHS is now on its eighth version (established by the UN in 2019). In February 2021, OSHA finally issued a proposed guideline that would serve as a hazard communication update to align with the Global Harmonized System (GHS) of Classification and Labeling of Chemicals. Because OSHA began its work before the UN's most recent update, the agency has noted that the HazCom update would more closely align with the seventh iteration of GHS but that the United States' most prominent trading partners were "all preparing to align" with the last version to ensure consistency.

According to a press release from OSHA, the agency "expects the HCS update will increase worker protections and reduce the incidence of chemical-related occupational illnesses and injuries by further improving the information on the labels and Safety Data Sheets for hazardous chemicals... Proposed modifications will also address issues since implementation of the 2012 standard and improve alignment with other federal agencies and Canada. OSHA has preliminarily determined that the proposed modifications would enhance the effectiveness of the standard by improving dissemination of hazard information so employees are more appropriately apprised of exposure to chemical hazards in the workplace."

The proposed OSHA rule can receive comments until April 19, 2021. In revision seven of GHS (as well as previous iterations that have taken place since 2012), there are some new developments that will be reflected in OSHA standards, including:

Other additions from previous iterations that will be reflected in the new HazCom standard will likely include new testing methods for oxidizing solids; simplified classifications and labeling summaries; new coding systems for hazard pictograms; new hazard classes and categories for desensitized explosives and pyrophoric gases; furthered clarity of hazard classifications for explosives, single exposure resulting in organ toxicity, aspiration hazards, and aquatic hazards; and new rules for the label design of small packages.

The bottom line is that most businesses have already been adhering to the standards of the latest GHS revisions. In reality, an updated Hazard Communication Standard by OSHA may not change the way you create warning labels for your products. That said, this update is crucial because some employers have often found ways to sidestep compliance in the past. This change will finally align these two systems more effectively and reduce the potential for confusion among all parties involved in the manufacture, distribution, and use of these kinds of products. When it comes to designing your labels, you'll need to consider both sets of standards for a more thorough final product that protects end users.

It's important to note that just because something isn't included in the newest HazCom update, that doesn't mean your business won't be responsible for adhering to safety practices outlined by GHS. Because GHS is updated every two years, it's seen as a more reliable benchmark for compliance. And because OSHA seems to always lag behind GHS, it's recommended that manufacturers, distributors, and employers that deal with hazard chemicals refer to both sets of standards to ensure safety.

So what are some of the guidelines included in the latest GHS revision? We'd like to draw your attention to the following GHS labeling requirements and safety classifications to keep in mind when designing your labels to adhere to the latest standards.

When designing your labels for hazardous chemicals and other similar products, it's essential to keep both GHS and HazCom standards in mind. Although these two systems will undoubtedly differ in certain ways, due to the policies of the agencies that regulate them, a thorough understanding of each is crucial for any manufacturer, distributor, or employer that works with toxic or hazardous agents.

With GHS now on its eighth revision and the OSHA HazCom Standard still catching up, businesses must stay alert to both current requirements and anticipated updates. Incorporating practices from newer GHS revisions can help bridge the gap and reduce confusion between international and domestic compliance obligations.

To simplify your labeling process, focus on the fundamentals:

Following these best practices makes chemical labeling more manageable and less risky, particularly when you work with an experienced provider.

Although keeping up with GHS labeling requirements and OSHA standards can be a barrier when designing your labels, it's a lot easier when you have an experienced printing company by your side. With the newest guidance outlined here, you'll be able to work with a reputable company when designing your labels for chemical products to ensure compliance and overall safety.

While the GHS framework was designed to be as user-friendly as possible, not every company has the resources to label their products. Our technological capabilities and experience as a leading label manufacturer ensure we can meet all your chemical labeling requirements -- enabling you to maintain GHS and OSHA compliance while simultaneously satisfying your customers’ specific needs.

Compliant labeling isn’t just about meeting standards – it’s about protecting workers, streamlining operations, avoiding costly violations, and maintaining trust. GHS and the OSHA HazCom Standard were designed to promote clarity in high-risk environments where every detail matters. Whether you're labeling for beauty and personal care packaging or healthcare packaging, every application calls for accuracy and care.

At Premium Label & Packaging, we simplify the complexity. From GHS compliant label development to international alignment with compliant clinical trial labels, we’re here to help.

Let’s talk about how we can simplify compliance and elevate your product labels. Contact us today to learn more about how we can support your unique labeling needs.

© 2024 Premium Label & Packaging Solutions | PLPS Sales Terms and Conditions